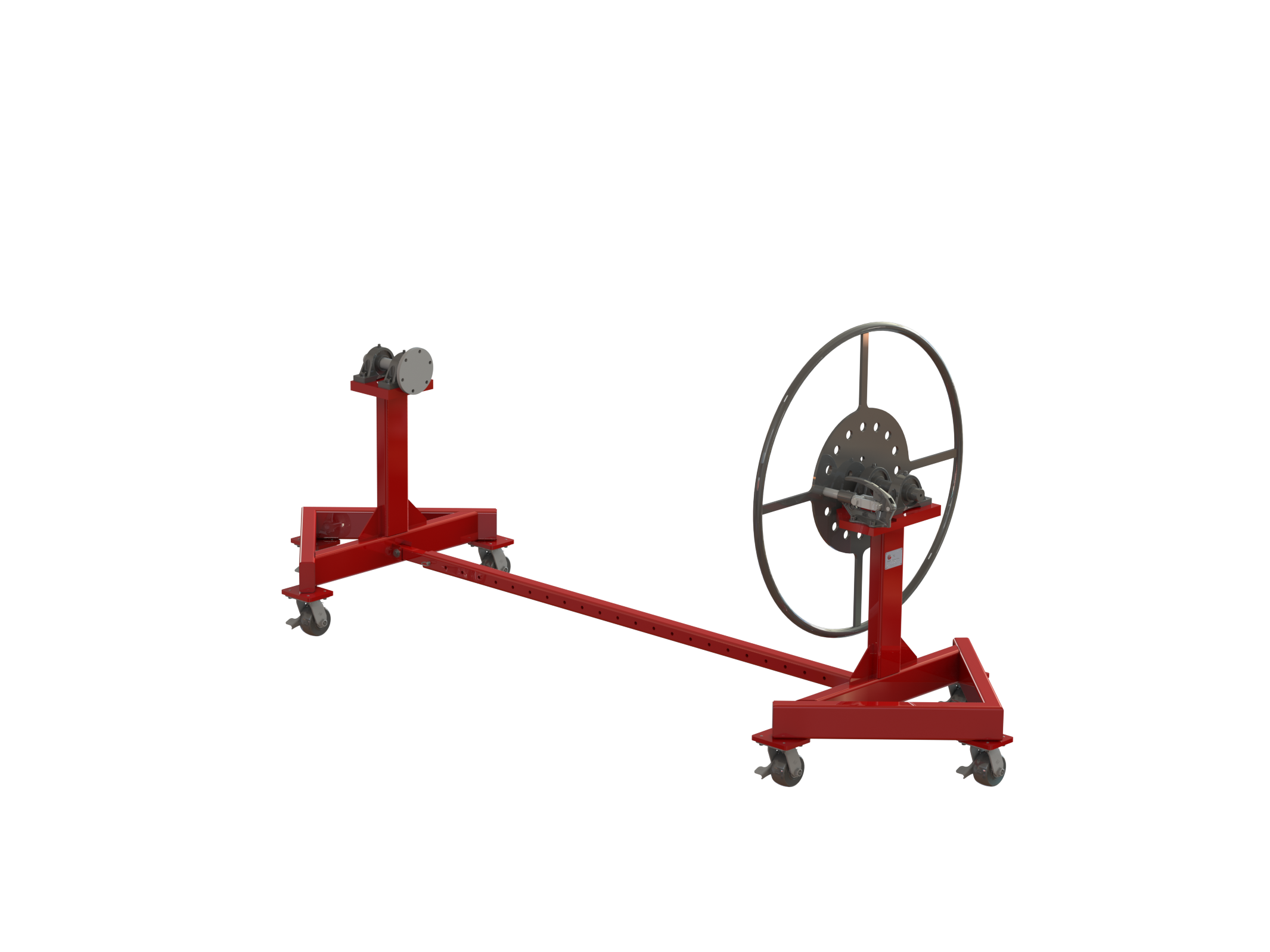

EZ-Trunnion-MHW

Using a trunnion when welding offers several advantages:

1. Enhanced Weld Quality: Trunnions provide a stable and adjustable platform for workpieces, ensuring precise alignment during welding. This leads to better weld quality with fewer defects.

2. Improved Welder Safety: Trunnions can securely hold and rotate heavy or bulky workpieces, reducing the physical strain on welders and minimizing the risk of accidents.

3. Increased Productivity: Rotating a workpiece on a trunnion allows welders to access different angles and positions easily, increasing efficiency and reducing the need for repositioning.

4. Versatility: Trunnions are adaptable and can be used for various welding applications, such as circular welds, longitudinal welds, and fillet welds.

5. Cost Savings: By improving weld quality and productivity, trunnions can lead to cost savings in terms of reduced rework and increased throughput.

Overall, using a trunnion in welding operations can contribute to better welds, safer working conditions, and increased efficiency.

Using a trunnion when welding offers several advantages:

1. Enhanced Weld Quality: Trunnions provide a stable and adjustable platform for workpieces, ensuring precise alignment during welding. This leads to better weld quality with fewer defects.

2. Improved Welder Safety: Trunnions can securely hold and rotate heavy or bulky workpieces, reducing the physical strain on welders and minimizing the risk of accidents.

3. Increased Productivity: Rotating a workpiece on a trunnion allows welders to access different angles and positions easily, increasing efficiency and reducing the need for repositioning.

4. Versatility: Trunnions are adaptable and can be used for various welding applications, such as circular welds, longitudinal welds, and fillet welds.

5. Cost Savings: By improving weld quality and productivity, trunnions can lead to cost savings in terms of reduced rework and increased throughput.

Overall, using a trunnion in welding operations can contribute to better welds, safer working conditions, and increased efficiency.

Using a trunnion when welding offers several advantages:

1. Enhanced Weld Quality: Trunnions provide a stable and adjustable platform for workpieces, ensuring precise alignment during welding. This leads to better weld quality with fewer defects.

2. Improved Welder Safety: Trunnions can securely hold and rotate heavy or bulky workpieces, reducing the physical strain on welders and minimizing the risk of accidents.

3. Increased Productivity: Rotating a workpiece on a trunnion allows welders to access different angles and positions easily, increasing efficiency and reducing the need for repositioning.

4. Versatility: Trunnions are adaptable and can be used for various welding applications, such as circular welds, longitudinal welds, and fillet welds.

5. Cost Savings: By improving weld quality and productivity, trunnions can lead to cost savings in terms of reduced rework and increased throughput.

Overall, using a trunnion in welding operations can contribute to better welds, safer working conditions, and increased efficiency.